How Do Strapping Machines Work?

Strapping machines are a crucial component in industries that deal with packaging and shipment. When packing boxes, securing pallets, or bundling products, strapping is a vital part of the process. But how do they work? Learn more about the basics of these machines and how they benefit your business.

What Is A Strapping Machine?

A strapping machine is a mechanical device that applies a strap to secure items together. Depending on the specific application, the machine typically uses polypropylene or polyester straps and is most commonly used to bundle packages or secure goods on pallets. These machines are used across various industries, including logistics, manufacturing, and retail, to provide a tight, secure wrap that prevents shifting during transportation.

How Do Strapping Machines Work?

Strapping machines secure products or packages with a strap, typically polypropylene or polyester, to hold them together tightly for transport or storage. The process involves several key steps:

- Feeding the Strap: The machine feeds the strap around the item or package.

- Tensioning: The machine pulls the strap tightly around the package to ensure a secure fit.

- Sealing: Once the strap is tensioned, the machine seals the strap, either by heat or friction, depending on the type of machine.

- Cutting: The machine then cuts off any excess strap, completing the strapping process.

Each type of strapping machine operates on these principles but varies in how they handle the steps of feeding, tensioning, and sealing.

Types of Strapping Machines

Strapping machines come in various forms, each designed to meet specific needs. Let’s break them down:

Manual Strapping Machines

Manual strapping machines are operated by hand and require a person to place the strap around the item, tension it, and seal it. These machines are ideal for small-scale operations or for businesses with lower-volume needs. They are compact and affordable but require more time and effort.

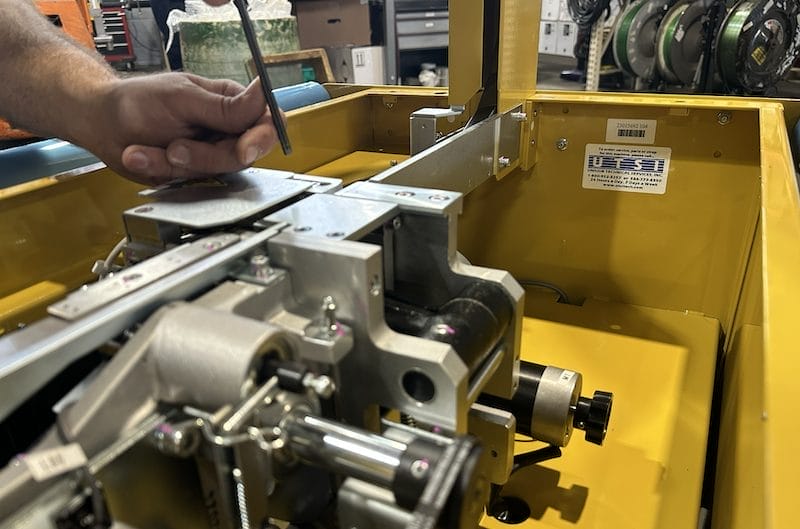

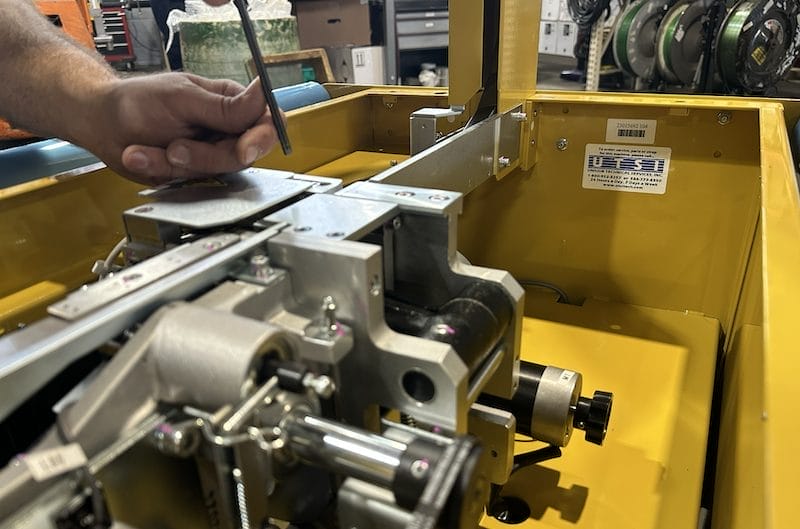

Automatic Strapping Machines

Automatic strapping machines are fully automated, which means they can handle the entire strapping process without human intervention. These machines feed the strap, tension it, and seal it all alone. They’re typically used in high-volume production environments where speed and efficiency are paramount. Automated machines help reduce labor costs and improve productivity, making them ideal for companies dealing with large packages or products.

Semi-Automatic Strapping Machines

Semi-automatic strapping machines are a hybrid of manual and automatic machines. They require the operator to load the package and initiate the process, but the machine handles the tensioning and sealing of the strap. These machines are perfect for businesses that want speedy automation but still need the flexibility of manual control.

What Is A Strapping Machine Good For?

Strapping machines are designed to secure items during shipping, preventing them from moving or getting damaged. They are beneficial for:

- Bundling products together for easy handling.

- Securing goods on pallets to prevent shifting during transportation.

- Reinforcing boxes and packages, ensuring their contents stay intact.

- Strapping machines are commonly used in packaging, warehousing, and logistics industries, where safety and organization are essential.

How Can A Strapping Machine Help Your Business?

Strapping machines can have a significant impact on your business by:

- Improving Efficiency: Whether manual, semi-automatic, or automatic, strapping machines save time compared to hand-tying straps or manually securing products. This increased efficiency helps businesses handle higher volumes without additional labor.

- Reducing Labor Costs: Automated and semi-automatic machines can reduce the need for manual labor, allowing your team to focus on other tasks. In turn, this leads to cost savings over time.

- Ensuring Consistency: Provide uniform tension and secure seals every time, which reduces human error. This consistency ensures that all items are packaged the same way, improving the quality and reliability of your product.

- Enhancing Safety: Properly strapped packages are less likely to shift during transport, reducing the risk of damage and improving safety for workers and products.

Ready to Invest in a Strapping Machine?

If you want to improve your packaging process efficiency and security, a strapping machine is the solution. Unique Technical Services can help you find the perfect fit for your business, whether you need a manual, semi-automatic, or fully automatic machine. Contact us today to learn more about our solutions and how we can streamline your operations.

24/7 SERVICE YOU CAN RELY ON

You can come to us or We can come to you, we support all major makes and models. We can even bring along required consumables upon request.

OUR SALES TEAM WILL GUIDE YOU

We specialize in Power strapping equipment, Stretch wrap systems, Shrink bundling systems, Conveyor systems, PLC support, Robotics.