24/7 SERVICE YOU CAN RELY ON

You can come to us or We can come to you, we support all major makes and models. We can even bring along required consumables upon request.

OUR SALES TEAM WILL GUIDE YOU

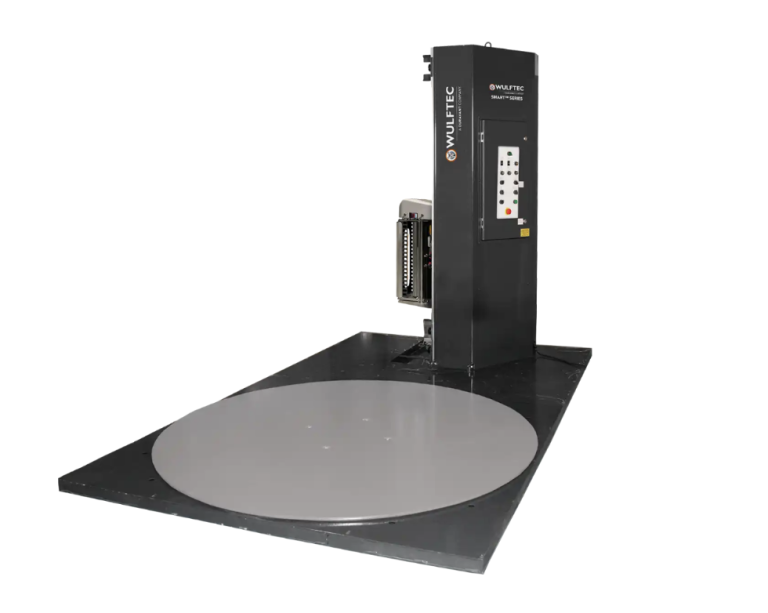

We specialize in Power strapping equipment, Stretch wrap systems, Shrink bundling systems, Conveyor systems, PLC support, Robotics.